Cure Monitoring of Polyurethane

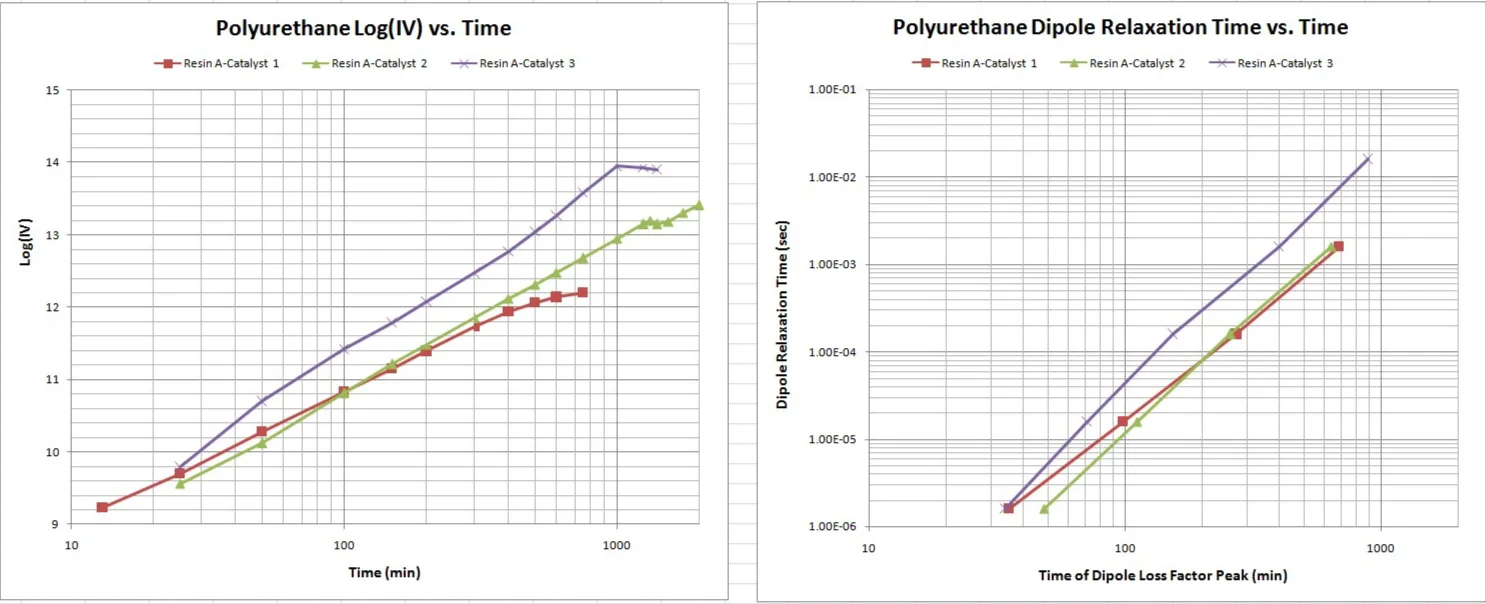

Lambient Technologies studied room temperature cures of a polyurethane resin with three different catalysts. An LT-451 Dielectric Cure Monitor made measurements during each test at excitation frequencies from 0.1 Hz to 100 kHz for 24 to 36 hours.

The change in ion viscosity, which is frequency independent resistivity, is often proportional to mechanical viscosity before gelation and proportional to modulus after gelation. Used properly, ion viscosity is a useful probe of cure state. Ion viscosity at room temperature is relatively low, however, and the effects of dipole rotation dominate the dielectric response for much of these cures over a range of frequencies. Therefore, it is important to know when valid ion viscosity may be extracted from dielectric data.

When dipole loss peaks are visible in the data, it is feasible to use dipole relaxation times to assess cure state.

Tests showed both the change of log(ion viscosity) and the change of log(dipole relaxation time) increase proportionally with log(cure time), allowing:

· Measurement of cure rate by the slope of log(ion viscosity) vs. log(time)

· Measurement of cure rate by the slope of log(dipole relaxation time) vs. log(time)

· Prediction of isothermal cure state by using cure rate information

Cure monitoring of polyurethane—ion viscosity and dipole relaxation time